Service Hotline:

+86-15996139765

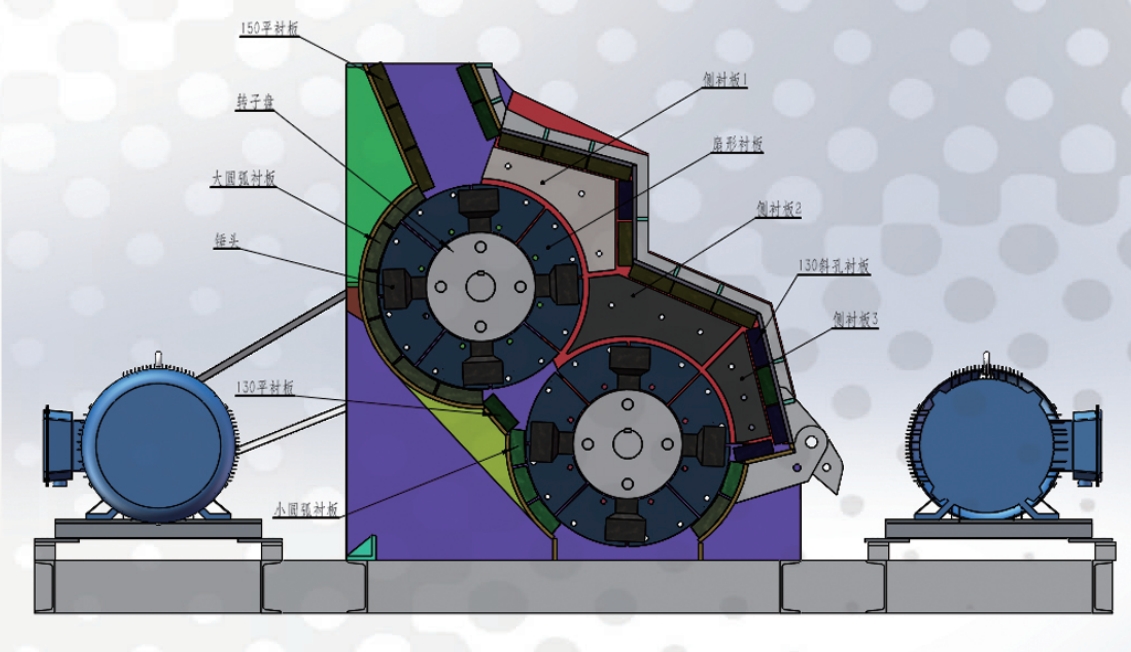

Double-Stage Crusher

INTRODUCE

Double-stage crusher is also called no-screen bottom double-stage crusher. In the design, the screen screen bottom is not used,there is no strict requirement for the moisture content of the material; and there is no paste blocking screen plate phenomenon,which can completely overcome the defects that the grate bottom is not easy to discharge due to the large moisture content of the raw material; In addition,in terms of capacity,the two-stage crusher is equivalent to two hammer crushers combined into one,and the two groups of hammer crushers rotors are combined into a whole and used in series,which is a new raw material crusher at present.

APPLICATION SCOPE

As a new type of crushing equipment,the two-stage crusher is mainly applicable to the crushing of calcite,limestone,slag,slag, shale,coal gangue,construction waste, construction fertilizer and other materials in brick and tile plants.It solves the problem of using gangue and coal slag as the additive and internal fuel of brick factory; Difficulty in Crushing High-wet Materials of Standard Brick and Hollow Brick Produced from Gangue and Shale.

CHARACTERISTIC

1. Unique shift clearance adjustment technology,no need to recover after the hammer head is worn,the moving position is repeatedly used,and one pair of hammer head can be used to top three pairs of hammer heads.

2. The discharging particle size is uniform, the crushing ratio is large, the output is high, the energy consumption is low,the materials can be crushed more than 20 tons per hour,and the cost of crushing each ton of coal slag is not more than 1.8 yuan.

3. Two-stage crushing is suitable for fine crushing of brittle materials, without blocking, with less dust and low noise.

4. The two-stage crusher shortens the retention time of materials in the crushing chamber and improves the service life of vulnerable parts.

5. The maintenance is fast,and the side door on the upper side of the crusher can be opened to facilitate the maintenance of the crusher.

6. High-alloy wear-resistant hammer head is adopted,and the hammer head and handle are combined for use. Only the hammer head is replaced,and the hammer handle is not replaced.

7. Two-way rotation of the two-stage crusher can facilitate even wear between the hammer head and the crushing tooth plate, and reduce the frequency of changing vulnerable parts after shutdown.

WORKING PRINCIPLE

During the two-stage crushing operation, driven by the dual motor,two sets of rotors connected in series rotate at high speed at the same time. The materials in the inner chamber of the machine are crushed by the superior rotor and immediately crushed again by the hammer head of the rapidly rotating lower rotor. The materials in the inner chamber are collided and crushed at high speed,so as to achieve the effect of hammering powder and material powder and form the slag particles with the discharge particle size less than 3mm. This particle size can completely meet the requirements of brick and tile manufacturers as internal combustion bricks.

Copyright:

Lianyungang Hengpeng Machinery Equipment

Record Number:

![]()

Technical Support: