Service Hotline:

+86-15996139765

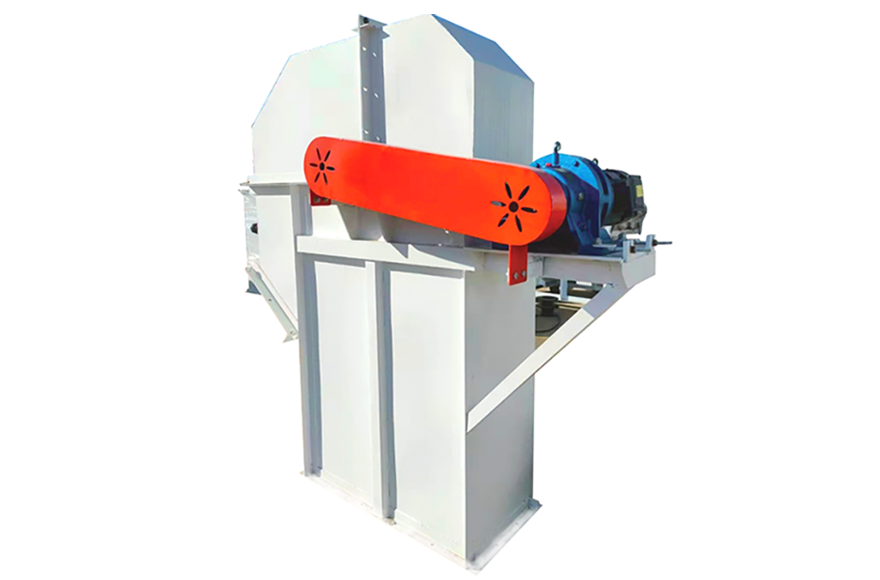

Ore Hoist

INTRODUCE

Bucket elevators are suitable for vertical transportation of powder, granular, and small bulk materials with a stacking density not exceeding 1.5t/m3, such as quartz sand,grain,coal,cement,crushed ore, etc.

The bucket elevator has a simple structure and smooth operation.It is used for excavation loading and centrifugal gravity unloading,with a material temperature not exceeding 60℃.Compared with traditional elevators,bucket elevators have higher conveying efficiency and more hopper forms,and should be preferred.

APPLICATION SCOPE

Bucket elevatoris suitable for lifting materials fromlow place to high place. After the supplied materials are put into the hopper through the vibrating table, the machine will automatically and continuously operate to transport materials upward.

CHARACTERISTIC

1. The type elevator has a wide lifting range and requires few types and characteristics of materials. It can not only lift general powdery and small particle materials,but also lift materials with high grinding ability. Good sealing performance and low environmental pollution.

2. Low driving power,adopting inflow feeding, induction unloading,and dense layout of large capacity hopper. There is almost no phenomenon of material return or excavation during material lifting,so there is less ineffective power.

3. With long service life,the feeding of the elevator is of inflow type,without bucket excavation,and there is little extrusion and collision between materials. The machine is designed to ensure less spillage of materials during feeding and unloading,reducing mechanical wear.

4. Good operational reliability,advanced design principles and processing methods ensure the reliability of the entire machine operation, with a fault free time exceeding20000 hours.

5. The lifting height is high,and the hoist operates smoothly,thus achieving a higher lifting height.

WORKING PRINCIPLE

The hopper of a bucket elevator scoops up the material from the storage below,lifts it to the top with a conveyor belt or transmission chain, bypasses the top wheel,and then flips downwards. The bucket elevator tilts the material into the receiving groove.The transmission belt of bucket elevators with transmission generally adopts rubber belts, which are installed on the lower or upper transmission rollers and the upper and lower directional rollers. Chain driven bucket elevators are generally equipped with two parallel transmission chains,with a pair of transmission sprockets above or below,and a pair of directional sprockets below or above. Bucket elevators are generally equipped with a casing to prevent dust from flying in the bucket elevator.

Copyright:

Lianyungang Hengpeng Machinery Equipment

Record Number:

![]()

Technical Support: