Service Hotline:

+86-15996139765

Sand Making Machine

INTRODUCE

The new sand making machine is different from traditional sand making equipment,for example,the frame is made of high wear-resistant material high

manganese steel,which is durable and has internal accessories added with alloys, which is more wear-resistant than traditional sand making machines and greatly improves the service life of the equipment. And all accessories can be completed through the upper part of the rack, which has the advantages of labor-saving and convenient.

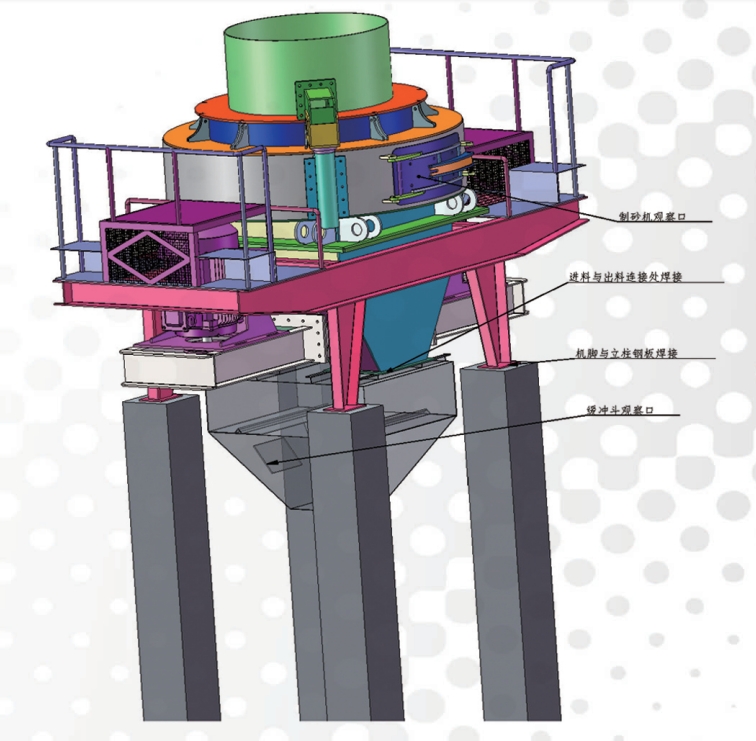

STRUCTURE

The sand making machineis generally composed ofafeeding hopper, classifier, crushing chamber, impeler, spindle assembly, bracket, base, transmission device, motor, lubrication system,etc

CHARACTERISTIC

1. Good product particle size: During the crushing process of sand making machine, the materials will impact and crush each other and will not contact with the metal components directly,so as to reduce the pollution, prolong the wearing time of machine, reduce the phenomenon of excessive crushing of materials and ensure the quality of products.

2. Non pollution: The impact sand making machine adopts a vortex crushing chamber, which cleverly circulates the airflow inside the vortex chamber during operation, eliminating dust pollution and meeting national environmental protection requirements.

3. Adjustable discharge particle size: During operation,the parameters of the sand making machine can be adjusted to fix the size of the discharge port.

4. High crushing capacity: Due to the use of diamond shaped combined impact blocks, the sand making machine greatly improves the wear resistance of the impact blocks and the crushing capacity of the sand making machine.

WORKING PRINCIPLE

The material to be crushed enters the crushing chamber from the feed inlet and is divided into two parts by the powder feeder. One part enters the high-speed rotating impeller and is driven by the impeller to rapidly accelerate the movement. Then,it is ejected from the three evenly distributed flow channels of the impeller at the speed of60-70m/s. First,it is impacted and crushed by the material falling from the powder feeder,and then impacted on the material lining layer in the vortex branch cavity together. Then,it is bounced back by the material layer and impacted obliquely upward to the top of the vortex chamber, The material curtain will be formed together with the materials ejected from the impeller passage due to the slant downward movement of the changed direction.In this way,each piece of material is crushed by at least two or more times of collision,friction and grinding in the crushing chamber. The material crushed to the appropriate particle size is discharged from the discharge opening at the lower part.

Copyright:

Lianyungang Hengpeng Machinery Equipment

Record Number:

![]()

Technical Support: